Leave Creativity to the Engineers, the Machines will do the Rest

Increasing efficiency of daily work while dealing with big data and challenging requirements was the theme of Antonio Di Carlo’s presentation at the European Altair Technology Conference (E-ATC) in Frankenthal, Germany (June 26th – 28th 2017).

Di Carlo is a Senior Mechanical Engineer at RUAG Space, a major supplier of space equipment with offices in 5 countries and currently 1300 employees. RUAG is a highly innovative company and an early adopter of new technology, as the example of the first 3D-printed space antenna suggests.

The development of space structures is a very demanding environment. Conflicting requirements, such as stiffness versus mass or structural strength versus thermal requirements, all under the permanent pressure of cost - must be juggled at all stages of development. Di Carlo expressed the necessity of automation to be competitive: “The objective is always to have engineers do the creative work and let the machines do what the machines can do [best].”

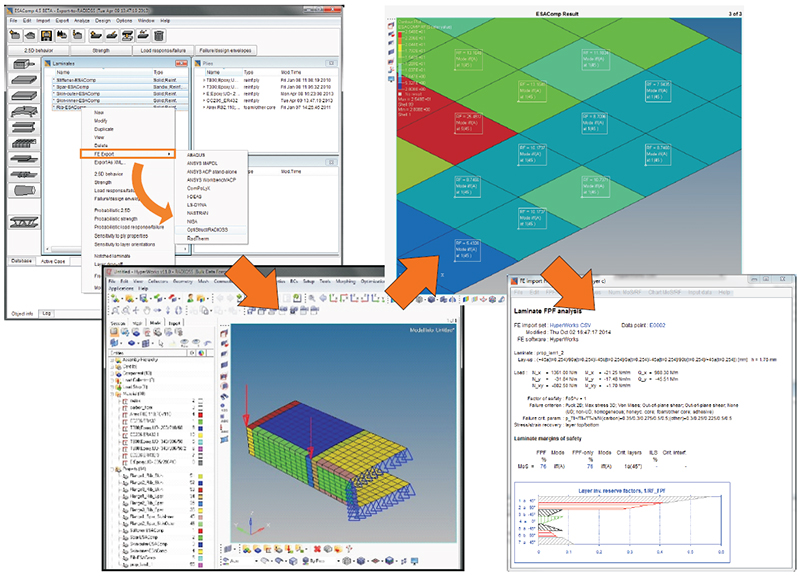

Altair and RUAG have been working jointly on a tool to identify the minimal margin of safety for frequency response analyses which works for any kind of laminate structures. The amount of data produced is huge when considering the number of investigated frequency points, load cases and layers. During development it soon became quite clear that the tool had to efficiently deal with gigabytes of data. It assembled all necessary element forces based on phase angle, amplitude and quickly identified the frequency points and layers with minimal margin of safety. Marginal safety plots were output to HyperView®. These and resultant tables were then published in reports. From there, critical parts were identified and later verified in ESAComp, Altair’s most recent tool for composites design and analysis.When asked about the efficiency of Altair’s development services, Di Carlos said: “It was a relatively quick development”. RUAG provided Altair with exact specifications which made a turnaround time of only 3 weeks possible. “I think it was a quite successful development from our side and we are happy with the results and the way it went with Altair’s support.”

The E-ATC in Frankenthal was Di Carlo’s second Altair technology conference. He appreciates the variety of customer presentations at Altair conferences, and the occasional fresh perspective he gets from listening to presentations even outside the Aerospace industry, triggering new ideas resulting in improved efficiency in his own daily work.

Author note: It will be interesting to learn of ideas inspired by this conference which may become instrumental to RUAG’s quest in increasing efficiency by freeing up the engineer’s time so that they can apply their full energy and experience in finding innovative solutions for the future.