Peak Performance as Ski Season Approaches

For some of us, the real excitement of the year comes not from the longer days and warmer temperatures but from the fall of the first snow and the start of a new season: ski season. The re-emergence of winter jackets is accompanied by ski goggles and a yearning to ride the nearest ropeway to the highest slope with the freshest snow.

A Rise in Safety

Ropeways are a core element of any ski resort, safely delivering passengers to the top of the slope for them to enjoy the ride back down. In these modern transport systems, flawless operation, comfort, and passenger safety are key engineering criteria for design. Utilizing a design method that ensures the engineers get it right the first time leads to high availability, higher profits, and higher customer satisfaction, enabling these ropeways to run at peak operational efficiency. This is why ropeway manufacturers use engineering software to ensure these requirements are met.

Take Doppelmayr for example. As a manufacturer of ropeways and innovative transport systems for urban and ski area, they need to ensure their products are of the highest quality and function properly. Recently they used Altair Inspire™ to analyze and redesign a bracket of a Doppelmayr lift station building. Previously, the seam weld of this bracket had failed a critical vibration test and so it was necessary to improve the design of the component to increase the strength and improve the fatigue-life of the connection, all while reducing weight.

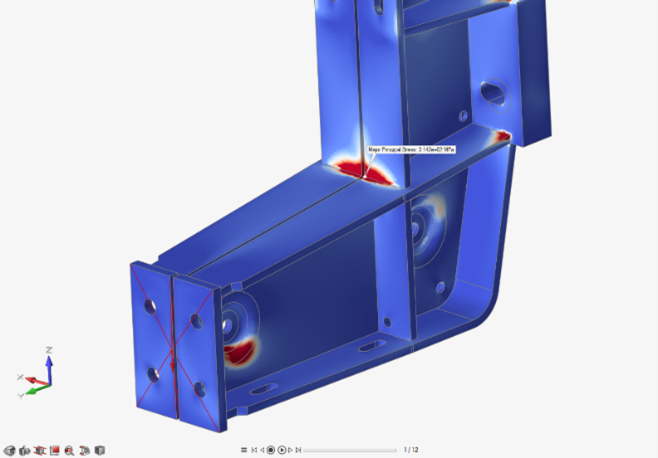

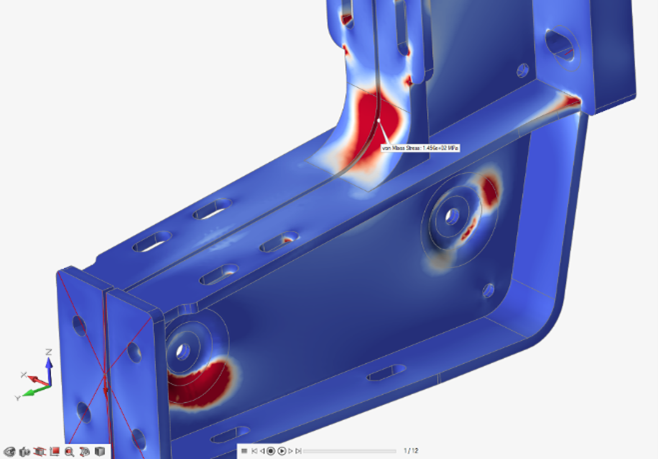

The brackets of a Doppelmayr lift station building

To assess the performance of the existing bracket effectively, Doppelmayr engineers created a CAD model and subjected it to the requirements of the component such as vibration caused during acceleration. This test revealed overstressing in a localised section of the part, leading to a redesign. The final design solution was a welded insert with a flame-cut profile and weld preparations. This ensured that the stress remained outside the weld seams, creating better stress distribution and an increased lifespan.

SimSolid’s solver gives the user structural analysis results in seconds to minutes without the need for manually meshing or geometry cleanup. After identifying the problem area, geometry modifications can be made directly to the model in Inspire, reanalyzed in SimSolid, and compared against the initial design, all without the need to switch and translate between multiple software interfaces.

The design with the overloaded area at the weld seams

Read the full case study here.

External Forces

Other than vibrational forces acting on specific components, external forces such has wind flow can impact the safety and design considerations. After all, these transport systems must consistently hold up against adverse weather conditions at high altitude. An understanding of how wind flow will affect the performance of this equipment therefore is crucial.

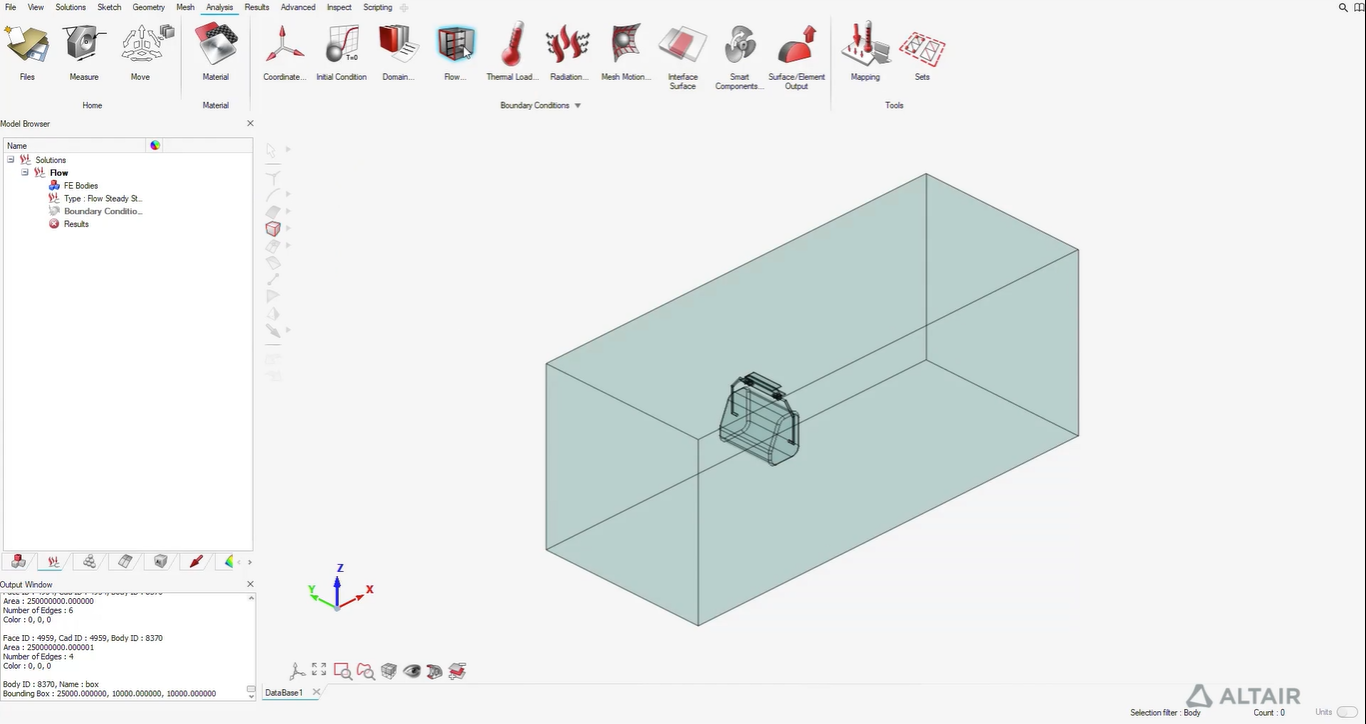

Altair SimLab™ is a process-oriented multidisciplinary simulation environment that accurately analyzes the performance of complex assemblies. Bridging the gap between the design and solver world, multiphysics analysis tools used for statics, dynamics, heat transfer, fluid flow, and electromagnetics are directly embedded into the software and accessed using the intuitive and self-explanatory interface. These solvers can be set up easily using highly automated modeling tasks that help to reduce the time spent creating finite element models and interpreting results.

Thanks to an easy model set up process and the elimination of manual meshing, the extraction and analysis of wind loads acting on the ropeway can be achieved more quickly and efficiently. Traditionally, an expert level knowledge of CFD would be needed to accurately set up and run a simulation of this nature, however SimLab’s workflows enable engineers to extract critical simulation insights, even for those without domain-specific expertise.

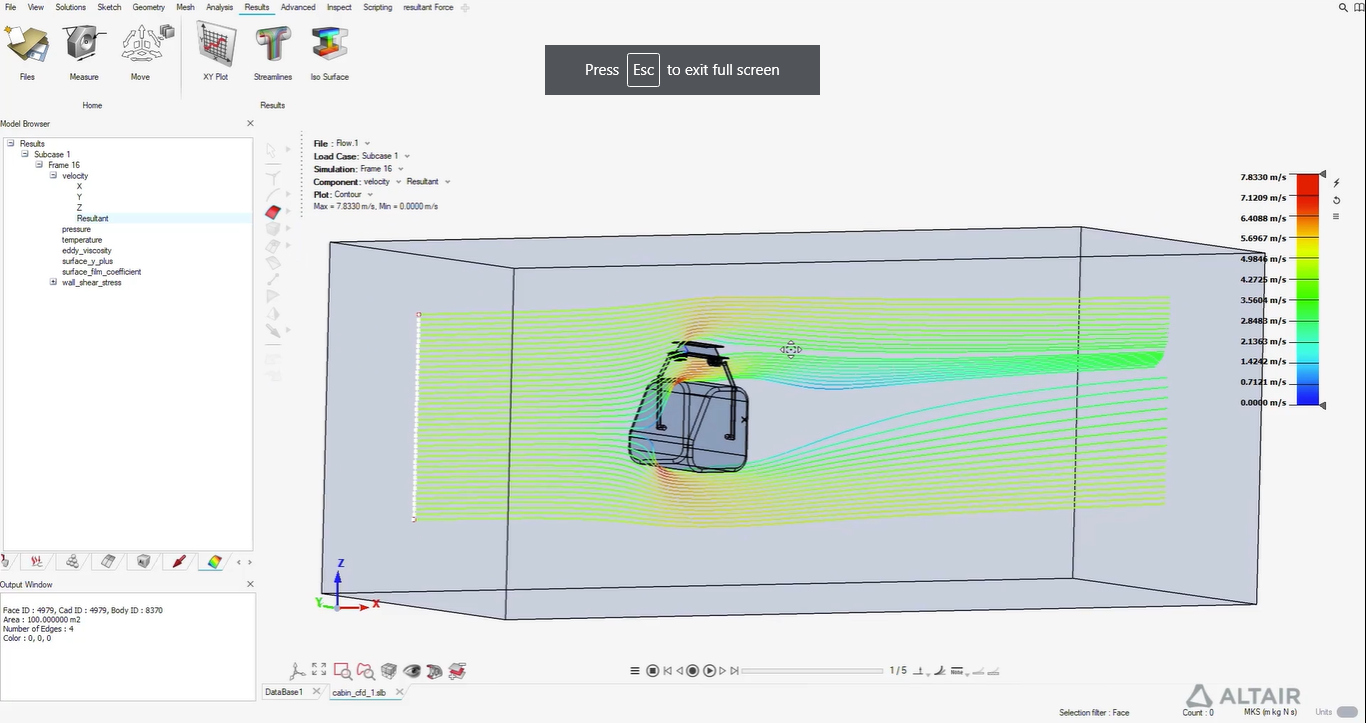

Simulation of wind loads on a ropeway with Altair SimLab

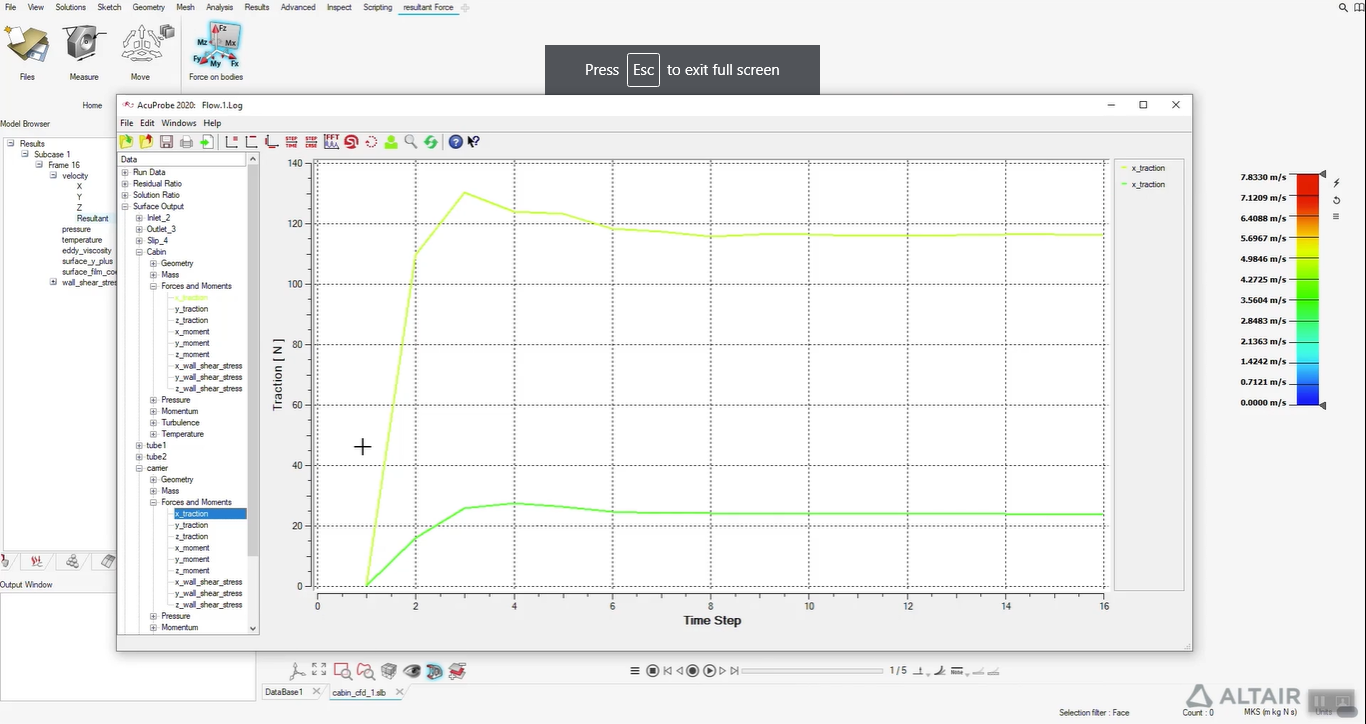

For post-processing, resultant forces acting on the body, cabin, and carrier can easily be viewed and plotted directly within the software.

Review of streamlines

Force on cabin and carrier

See below for the full video of this process.

[embed]https://altair-2.wistia.com/medias/wusio4x73s[/embed]

For many of us, the main requirements of a successful ski holiday are fresh snow, beautiful sunshine, and a well-stocked bar. Behind the scenes however, there are many processes involved to ensure safety and peak operational efficiency. Altair products such as Inspire™ and SimLab™ enable manufacturers to solve the toughest design challenges, drive better decisions, and create innovative solutions.