Mechatronics and the Myth of Simultaneous Engineering

Automation is everywhere. It is in our personal and professional lives, and particularly in manufacturing it evolves each day. As these automation levels continue to grow, so too will robotic applications to help shape the future of manufacturing more than ever before.

Today, state-of-the-art mechanical machinery is efficient, connected, and collaborates with humans and robots alike. In fact, recent innovations have a robot wrapping itself around a human in the form of an exoskeleton to create even further productivity improvements. This dynamic continues to grow when looking at the robotics and machinery industries.

Robotics and automation – growth sector in the machinery industry for higher efficiency. Source: Quest Trend Magazine

The digitalization gap

Many manufacturing machinery and automation equipment companies are focused on transforming their products by equipping them with smart capabilities. This will push the productivity limits closer to what is physically feasible, enabling predictive maintenance and further smart product attributes. This transformation of products and services must also be reflected in their development processes and has implications for the organizational structure of the companies and the composition of the development teams.

By using smart technology, companies use software developers to help with service and decision-making support based on the data collected and analyzed with the help of artificial intelligence (AI) algorithms. With the increased level of complexity and the need to realize tight production deadlines with little down time, a holistic view of the system becomes critical to identify areas for optimization.

While the trend for marketing automation grows, equipment manufacturers are still approaching next-gen automation from a traditional standpoint. While digital twin has dominated the headlines of many engineering magazines, how to make digitalization happen still remains an open question for many chief engineers.

According to a 2017 research study from the Mechanical Engineering Industry Association (VDMA), a significant number of machine builders don’t apply simulation technology when building their equipment. However, this is changing as the simulation and analysis segment continues to grow in a dynamic PLM market.

The simulation and analysis segment continue to grow in a dynamic PLM market. Source: CIMdata

“Build it, paint it, add controls to it,” is still an often-heard mantra for engineers. Many engineering decision-makers know that if the industry keeps developing products as they do today, they will stop developing anything by the end of this decade. A digitalization strategy is required to maintain competitiveness and sustainability.

But how can simultaneous engineering processes become more efficient through virtualization when the development and testing of a control system for heavy-duty actuators happens after the mechanical system is finished? The risk of testing a control strategy on the final hardware becomes high. If the control strategy is not mature enough it is likely to destroy an expensive prototype. If one starts too conservatively the commissioning becomes a lengthy process and leads to an incalculable delivery start.

Quality can only increase when cross-functional collaboration allows for simultaneous engineering. The output can only be raised when quality risks and missed productivity goals are identified with holistic virtual testing.

How do digital twins help solve mechatronic challenges?

Altair digital twin integration platform

Altair defines a digital twin as a virtual representation of a product that supports decision making during the development phase, helps to optimize the performance of the product during operation, and provides insights for closing the feedback loop for continuous development. This is driven by simulation models or operational data.

Defining the digital twins in detail is driven by the needs of each company. The virtual representation can be driven by the physical phenomena observed in a simulation, which can then be built from the aggregated data-points of the operation and ideally combined to gain more insight.

Simulation silos prevent innovation

Pushing the boundaries and making machines run faster without compromising quality is a typical development task. But when the system's limits are reached, where should one look for productivity gains? How should problems be addressed when out-of-spec deformations occur during highly dynamic operations and those deformations further hinder productivity gains and possibly compromise quality?

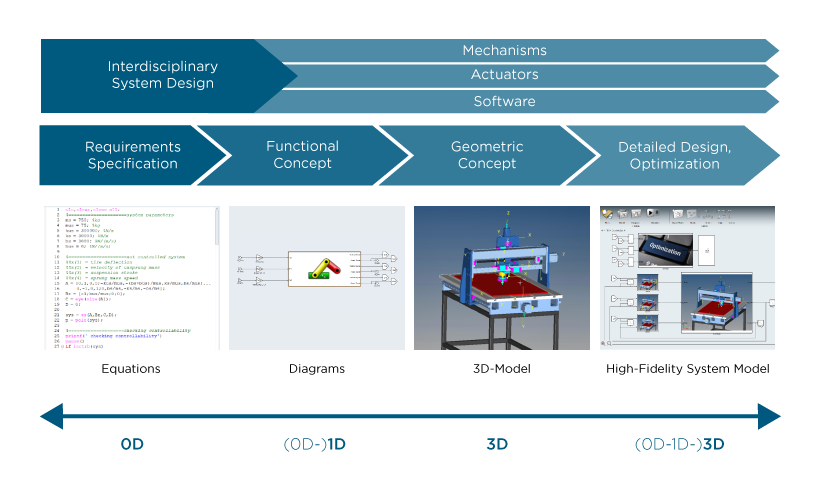

System simulation may be the answer with its digital representation of the machine with interdisciplinary data and different abstraction levels throughout the development process. Depending on the task, it can represent the individual elements of a mechatronic system precisely and efficiently.

In some industries, like aerospace and automotive, the adoption of computer-aided engineering (CAE) technology is a fundamental part of every supply chain development process. The investment in the technology reaches back several decades and best-in-class processes have been established utilizing the best tools available. But creating a holistic systems view is challenging. Two key factors must work in order to deliver on that comprehensive view:

- Openness and interoperability of the individual tools

- Communication between development disciplines and departments.

Development silos – Heterogenous and disconnected development responsibilities increase the risk of delayed production, delivery and cost control.

Virtual testing is incomplete

In many organizations, there is no CAE department and virtual testing is incomplete. Design changes to the structure can only be tested in combination with the final hardware. When the mechanical design and control system engineering is sequential, the structure, actuators and control system cannot be tested prior to the prototype. Consequently, the control engineers must fix what was not solved on the mechanical side.

Keeping development disciplines separate makes it difficult to identify the problem. Instead of a cost-efficient solution with an adaption to the controller or the control strategy, extensive changes of the kinematics or the structure must be made.

When the next generation of development requirements need to go further, the decision maker must be able to identify the optimization potential to make it better or more cost efficient. Having an early system understanding increases confidence in the system and provides for a path forward.

Only when the different domains of the system are understood, optimization becomes possible.

Holistic and the right size is the digital twin you want

What is the alternative to the scenario described above?

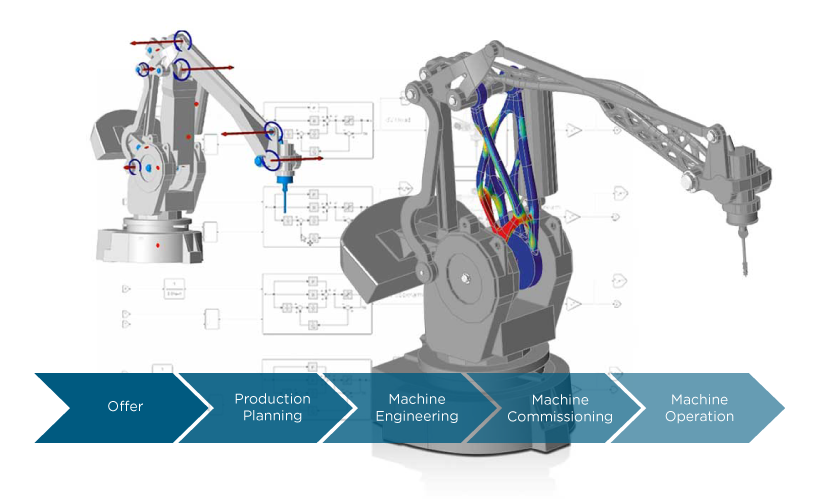

A system simulation of the actuators and the control system, the kinematics, the dynamic effects, the flexibility of the structure, as well as all the elements represented as individual elements of the product with appropriate precision levels and efficiencies.

Only a holistic digital product representation allows system level decisions and the identification of optimization potential. The collaboration of different domain experts in a unified environment ensures consistent and synchronous workflows, facilitates quicker and more profound decisions, and accelerates successful product development. Sequential work is avoided and tasks historically dependent on each other like, controller design and optimization, can be performed in parallel.

The simultaneous engineering of mechatronic systems is a multidisciplinary art. To be efficient holistic simulations must allow different levels of resolution. Flexibility to choose the required abstraction of the system representation is a success factor.

To be efficient, the simulation model and co-simulated sub systems must continue to evolve and grow based on the answers the whole system being asked to provide. To check the requirements with a simple kinematics model, the CAD models are converted into a functional multibody model to perform force and performances evaluation. From this, detailed loads can be extracted. By adding further details to the multibody model in form of flex bodies, the precision can be increased as required.

In co-simulation of the control system model, the actuators model and dynamic structure model, the system behavior can be assessed holistically. This sets the ground for system optimization and prepares the virtual commissioning of the system.

The higher accuracy level of the machine model through the added dynamic behavior and the flexibility allows an early optimization of the control strategy and the control parameters. The controls code can be tested early, and optimization potential can be identified. The structural development benefits from complete and exact loading conditions also allow further optimization to reach efficiency targets.

The digital twin design process drives system understanding to achieve a better design, enables higher operational efficiency and reduced implementation risks.

Way forward

Efficient product development is only possible if the product can be digitally integrated and on various abstraction levels throughout the entire development process. It is critical to represent individual elements of a mechatronic system precisely and efficiently. A holistic digital product representation allows for system-level decisions and optimization potential.

The collaboration of different domain experts in a unified environment ensures consistent and synchronous workflows, facilitates better decisions, and accelerates product development.

Altair can deliver a holistic environment with a flexible licensing system, backed by a strong technical organization to make it work. Altair understands the individual representations of your product, the interplay of its components and will help enable you to leverage your existing investments in reusing existing models and integrations. You have access to all modules that will represent the product comprehensively, co-simulate, co-work, interconnect, innovate and scale efficiently.

|  |

System modelling enables collaborative engineering, combines knowledge, and allows true simultaneous engineering to occur.

Development based on experience often means that you know what happens, but you don’t know why. The use of digital twins during development helps convert empirical knowledge into physical knowledge. This is a valid foundation for optimization.

Download our free whitepaper to learn how MX3D drives robot customization with a digital twin design process.