4 Common Issues Faced When Developing Vehicles Using CAE

The second of a four-part series on Automotive NVH comfort, these series are based on the paper, “Improving Vehicle NVH CAE Prediction Capability to Prevent Expensive Late Design Changes” written by Andrew Burke, Global NVH Manager at Altair. To view part one of the series, click here.

Vehicle customers now expect a high level of refinement. This coupled with the market trends discussed in part one of this blog series presents many challenges for NVH (Noise, Vibration, and Harshness) Engineers. CAE is widely recognized as an essential part of the NVH design process. However, methods and procedures must be continually reviewed and developed if design and business challenges are to be met.

Common issues that are faced when developing vehicles using CAE are:Late Design Changes and Customer Complaints

Unexpected NVH issues can be discovered during design verification vehicle testing. This can lead to very expensive program and production delays until the issue is understood and resolved. At this stage, design freedom is limited and solutions often repair issues but without dealing with the underlying causes, usually adding weight and significant cost. Depending on the history of the NVH issue, this situation can be viewed as a failing of CAE to detect and resolve issues before hardware manufacture and testing.

Customers that have purchased a vehicle and discovered a NVH related issue, can request assessment and rectification under warranty. Warranty issues are not only expensive to investigate and fix, but also lead to a degradation of the perception of quality and damage to brand image. These issues indicate a failing of both CAE and testing to detect a potential NVH problem.

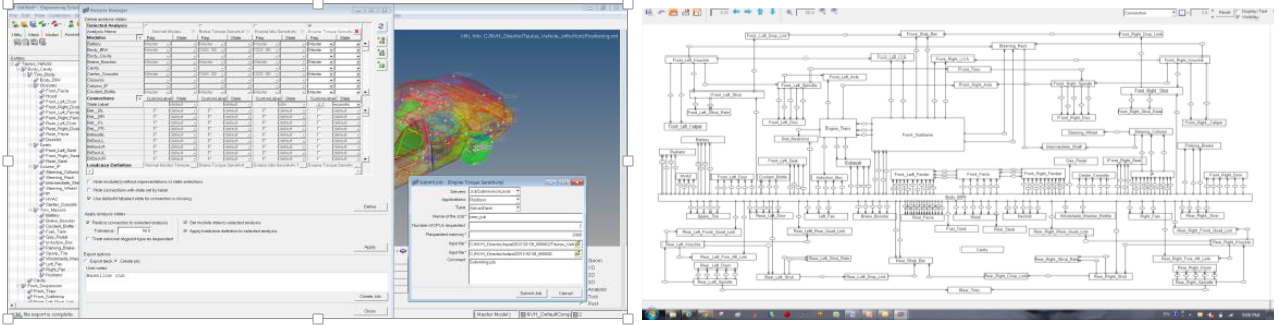

Design Lead Time is too LongDesired design and development lead times are often not achieved. This situation can be improved through the use of efficient and dedicated CAE tools to rapidly build models and minimize user error. Full vehicle simulation is essential in understanding system level behavior and performance due to real world events. Many companies limit their analysis capabilities to the component level due to the complexities of full vehicle model building and accurate load case representation. This is the basis for NVH Director, shown in Figure 1. The software has been designed to handle the complexities of NVH full vehicle model building and load case setup.

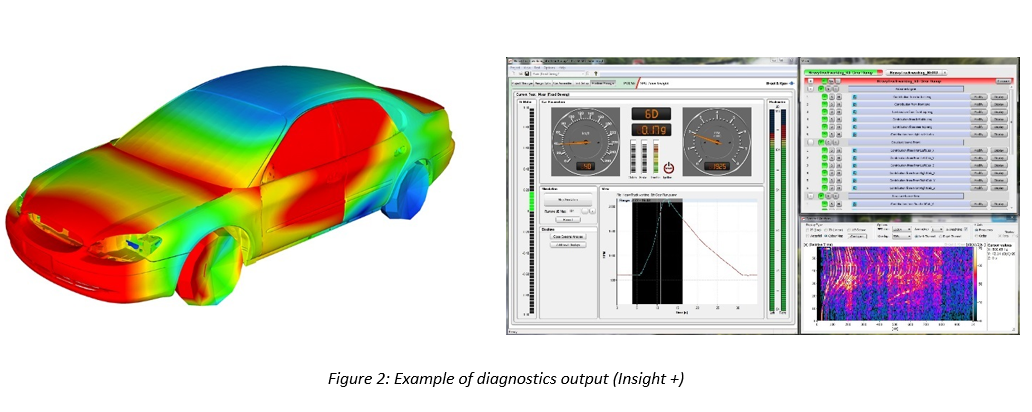

Lead time is also reduced by developments in solver technology to run analysis faster and with features specifically designed for NVH. Diagnostic output and post processing tools are also very important to rapidly investigate, understand and ultimately solve issues. Figure 2 shows an example of a diagnostic output.

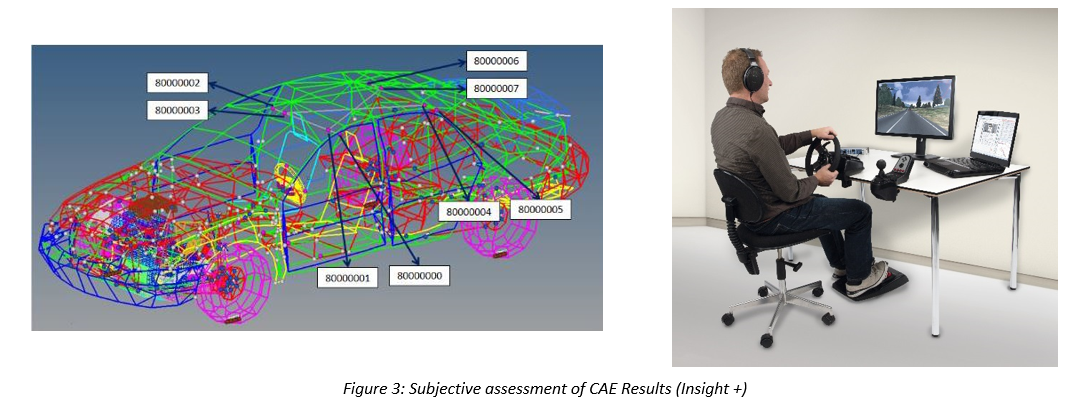

NVH objective performance is measured and predicted during vehicle development, but ultimately NVH performance is subjective and open to human interpretation. Efforts are made to present graphical data in a way that takes into account human perception but this still can be misleading compared to actual assessments. To address this, an interface has been developed that allows CAE results to be directly read into simulator software. This then facilitates noise and vibration subjective assessment. The categories of simulation are 1. Full vehicle – to provide an interactive driving experience with noise, vibration and visualization in a real vehicle. 2. Desk top - to provide and interactive driving experience with noise and visualization at a desk. 3. Headphones – noise assessment of a fixed vehicle operation condition, as shown in Figure 3. Option 3 puts noise assessment easily into the hands of the CAE analyst allowing subjective design decisions to be made.

Simulator technology facilitates back to back design comparisons and jury assessments to be made without prototype vehicle testing and without downtime between assessments for vehicle refit, which makes direct comparisons more difficult. Design decisions can be made in a simulator environment quickly and effectively thereby reducing lead time and prototype vehicle costs.

Mass Target not Achieved

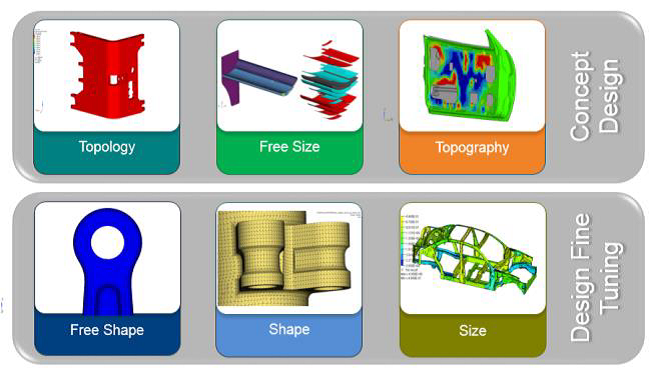

Mass is often seen as a consequence of achieving performance and can be a secondary consideration. That is until the end of a vehicle program when it is realized that mass targets are not being achieved. To address this, routine use should be made of CAE optimization technology. Figure 4 illustrates the general structural optimization capabilities that are available at concept level and for design fine tuning.

Multi-disciplinary optimization (MDO) should also be routinely employed for attribute balancing that includes the consideration of mass as an attribute. An example of a MDO study that considered crash, NVH, comfort and dynamics performance to reduce mass is shown in Figure 5.

Finally, NVH prediction capability should be improved to reduce the risk of adding mass late in a vehicle program to resolve NVH issues.

Prototype Build and Testing Costs Too High

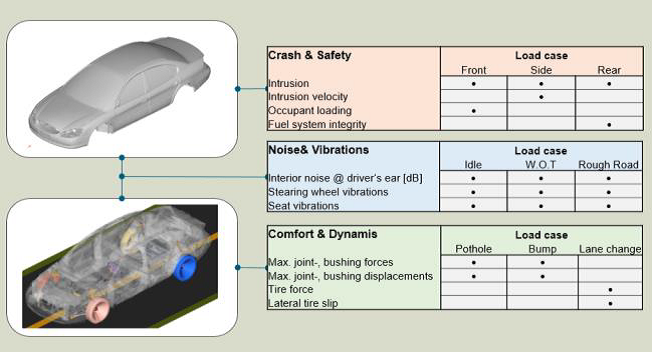

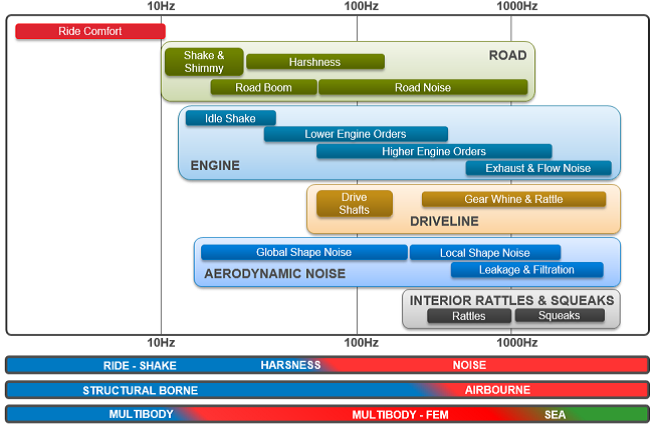

Today a significant part of NVH sign off testing cannot be simulated with CAE. To reduce prototype build and testing costs it is essential that CAE methods are developed to provide the capability to predict more sign off testing. These simulations can be very complex, requiring a multi-physics and full frequency range approach. Figure 6 shows general NVH performance criteria, the frequency range this covers and the appropriate CAE simulation method. It can be seen that to cover the entire frequency range a multi-method approach is required.

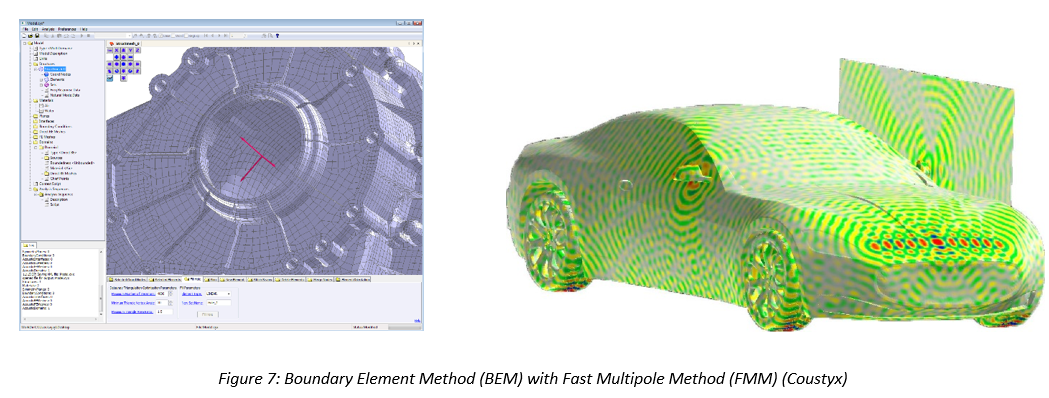

Automotive interior cabin noise, in the structure borne range, is most commonly simulated using a FEM approach. In combination with FEM, boundary element methods (BEM) are also used, for both interior and exterior noise applications, Figure 7. Solvers employing fast multipole method (FMM) technology can perform fast acoustic analysis on very large models.

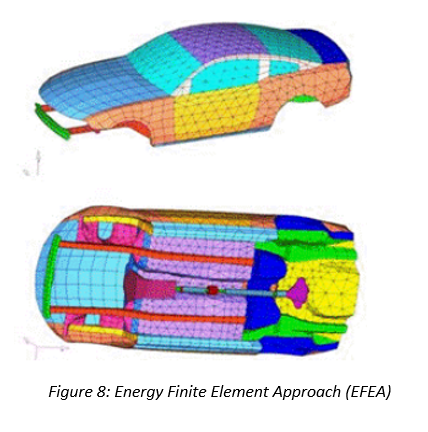

As the frequency increases, standard FEM becomes less predictive and other methods are adopted. Energy finite element analysis (EFEA), Figure 8, is an approach that is suitable for mid to high frequency vibro-acoustic simulations. An EFEA model is much coarser, and solver time is typically faster than a FEM approach. This is due to equations being energy based instead of displacement based.

As the frequency increases, standard FEM becomes less predictive and other methods are adopted. Energy finite element analysis (EFEA), Figure 8, is an approach that is suitable for mid to high frequency vibro-acoustic simulations. An EFEA model is much coarser, and solver time is typically faster than a FEM approach. This is due to equations being energy based instead of displacement based.

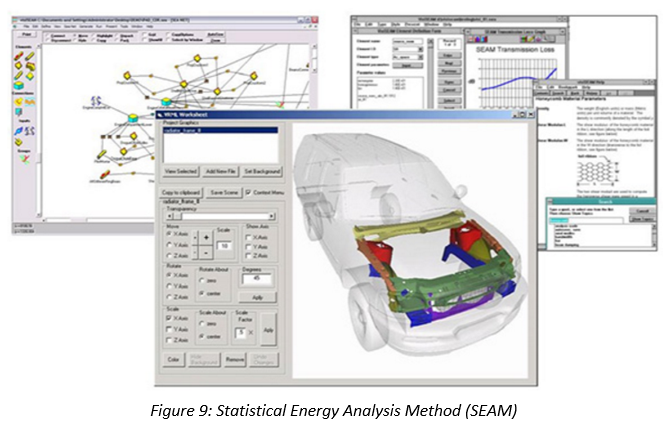

High frequency noise analysis is also carried out using statistical energy methods (SEAM), Figure 9, predicting mean response and variance set to confidence levels. The system being analyzed is divided into a set of substructures and acoustic elements. The flow of energy between subsystems is proportional to modal energy, and coupling factors are derived. The resulting equations are solved for the modal energy and response of each subsystem.

Coming soon, Game Changer: Including More Physical Effects in CAE Simulation Improves NVH Prediction Capability. Check back in for the third post in the series or you can download the full paper here.